Comprehensive Guide to Lift Repair Companies Near Me for Effective Lift Maintenance

Wiki Article

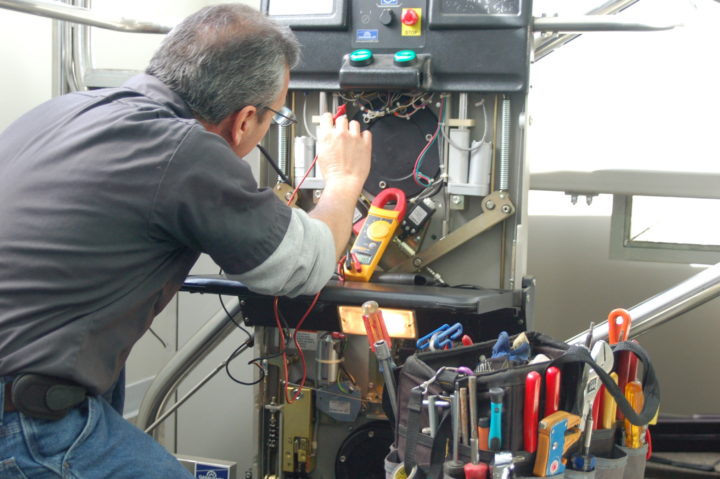

Vital Variables to Take Into Consideration for Lift Maintenance

When it comes to the safe and reliable procedure of elevators, considering crucial maintenance factors is extremely important. It is crucial for building supervisors and maintenance employees to stay in advance of these factors to copyright the lift's performance standards and compliance needs.Regular Evaluation Schedules

Conducting normal examinations not just enhances the total efficiency of the elevator yet additionally plays a vital function in complying with safety and security guidelines and industry criteria. It makes sure that the elevator runs smoothly, minimizing the danger of unexpected breakdowns that might hassle passengers or compromise safety and security. Furthermore, regular assessments add to lengthening the lifespan of the lift equipment, inevitably decreasing upkeep costs and downtime.

To simplify the evaluation procedure, numerous structure owners companion with qualified elevator upkeep companies that focus on conducting complete assessments and supplying punctual maintenance solutions. By focusing on regular assessment timetables, stakeholders can support the safety and security, reliability, and effectiveness of their lift systems.

Proper Lubrication Methods

Reliable lubrication practices are necessary for keeping the ideal efficiency and durability of elevator components. Appropriate lubrication techniques play a crucial duty in preventing damage on moving parts, minimizing rubbing, and ensuring smooth operation of the elevator system. When it concerns lift upkeep, making use of the right lubricants in the appropriate quantities at the suggested periods is crucial to lessening and stopping pricey fixings downtime.To ensure proper lubrication, elevator technicians should comply with producer guidelines concerning the type of lubricant to be used for specific components such as bearings, gears, and overview rails - lift maintenance company. Over-lubrication can draw in dust and debris, resulting in component malfunctions, while under-lubrication can cause enhanced friction and early wear. Regularly set up lubrication upkeep must be included in the general lift maintenance plan to maintain the system running effectively and safely

Checking Tear and put on

Lift upkeep personnel ought to carry out regular inspections to determine indications of wear on vital parts such as ropes, sheaves, guide rails, and bearings. Additionally, keeping comprehensive upkeep documents can assist in tracking the wear patterns of lift parts over time, permitting for anticipating upkeep preparation. By closely keeping track of wear and tear, maintenance groups can attend to concerns proactively prior to they rise right into pricey repairs or unexpected downtime, ensuring the safe and efficient operation of the redirected here elevator system.

Safety Conformity Checks

Carrying out complete security compliance checks is essential in ensuring the lift system satisfies all functional requirements and governing requirements. These checks also include verifying that the lift's capability limits, rate, and emergency interaction systems are in line with safety criteria. Furthermore, adherence to safety and security compliance checks can prevent crashes, decrease responsibility risks for structure owners, and expand the lifespan of the lift system.

Emergency Action Planning

Due to the critical value of safety conformity checks in preserving elevator systems, a durable emergency feedback see this page planning approach is critical to promptly and successfully address unexpected incidents. lift engineer course. Emergency action preparation for elevators includes aggressive measures to guarantee the security of travelers and upkeep employees in the event of emergencies such as power blackouts, entrapments, or mechanical failingsKey elements of an efficient emergency situation feedback plan include establishing clear communication procedures, supplying normal training to team on emergency situation procedures, maintaining updated emergency situation call lists, and conducting routine drills to practice action activities. Additionally, it is important to have actually marked employees in charge of working with emergency reactions and making certain that necessary tools, such as emergency situation lighting and communication gadgets, are in working order.

Conclusion

Finally, it is critical to focus on routine examination schedules, appropriate lubrication methods, keeping an eye on damage, safety and security conformity checks, and emergency reaction planning for elevator upkeep. By applying these necessary aspects, building owners can make certain the safety and security and effectiveness of their elevators, ultimately lowering the danger of breakdowns and mishaps. Constant maintenance techniques are vital for prolonging the life-span of elevators and ensuring the health of individuals that depend on them for transportation.check this site out Routinely set up lubrication maintenance should be consisted of in the overall lift maintenance strategy to keep the system running successfully and safely.

Lift maintenance employees ought to conduct routine inspections to determine signs of wear on crucial components such as ropes, sheaves, overview rails, and bearings. Additionally, maintaining detailed upkeep records can help in tracking the wear patterns of lift elements over time, permitting for predictive upkeep planning. By very closely checking wear and tear, maintenance groups can deal with concerns proactively prior to they rise into pricey repair work or unanticipated downtime, making sure the safe and effective procedure of the lift system.

Report this wiki page